The DIY Filament Box is an individually planned box for storing filament spools to protect them from dust and moisture. Thanks to the filament feedthroughs, fialment can be printed straight out of the box. The filament spools are rotatably mounted and filament can be unwinded directly via a PTFE tube. During planning and operation, particular attention must be paid to ensuring that the spools can be rotated freely and the filament can be removed smoothly.

Safety Guidelines

Safety first! Read and follow the assembly instructions and the operating manual!

Read the entire assembly instructions and operating manual carefully and adhere to the instructions and safety guidelines. If anything is unclear, simply contact support (support@3d-druck-vorlagen.de). In the 3D print files for this project, the instructions and operation manual are also attached as PDF, keep it because you may need it later. A one-page quick guide is also included in the files with a link to this page – you will always find the latest version of the instructions and the operating manual here. If you are giving the project to someone else, then print out the instructions, operation manual and, above all, the safety instructions and pass them on with the project.

Before you start the project, also check whether the project meets the safety regulations of your respective country.

Legend: Warnings and Symbols

Safety instructions for this 3D printing project

Never lock living beings (children, animals) in the box! Danger of suffocation, danger to life! Only for storing commercially available filament!

Keep the filament box safe and out of the reach of children and animals, the filament dry box is not a toy!

Do not leave the 3D printer unattended while printing! If the printing is interrupted or the 3D printer makes unusual noises, switch off the 3D printer immediately, check the filament box and the filament feed!

Also read through, follow and keep the operation manuals and safety instructions for the purchased parts!

Attention for all purchased parts: Before assembling, check whether they meet the safety regulations in your country and whether the dimensions, function and stability are fine. Repeat this safety check at regular intervals and before using the project. If a part is damaged or unsuitable, do not continue to use the project until the affected part has been replaced.

Attention for all self-printed parts: Due to incorrectly set printing parameters, poor material, incorrect material selection, poor layer adhesion and other reasons, these can sometimes not meet the requirements needed on them and thus break, fail or their functionality cannot be guaranteed. In the event of a break, the parts can splinter and the fracture surface leave sharp edges. Take particular care when replacing these parts, there is a risk of cuts! Check 3D printed parts for cracks, stability and functionality at regular intervals and before using the project. If a part is damaged or unsuitable, do not continue to use the project until the broken part has been replaced with a new, improved part.

Always place the filament dry box horizontally and at a stable, safe location.

Inserting the filament spools:

Move the single pulleys on the threaded rods so that the filament spool to be inserted is securely and centrally on the four single pulleys after it has been inserted. If using wide pullys take care that the spools stands securely and centrally on the two wide pulleys.

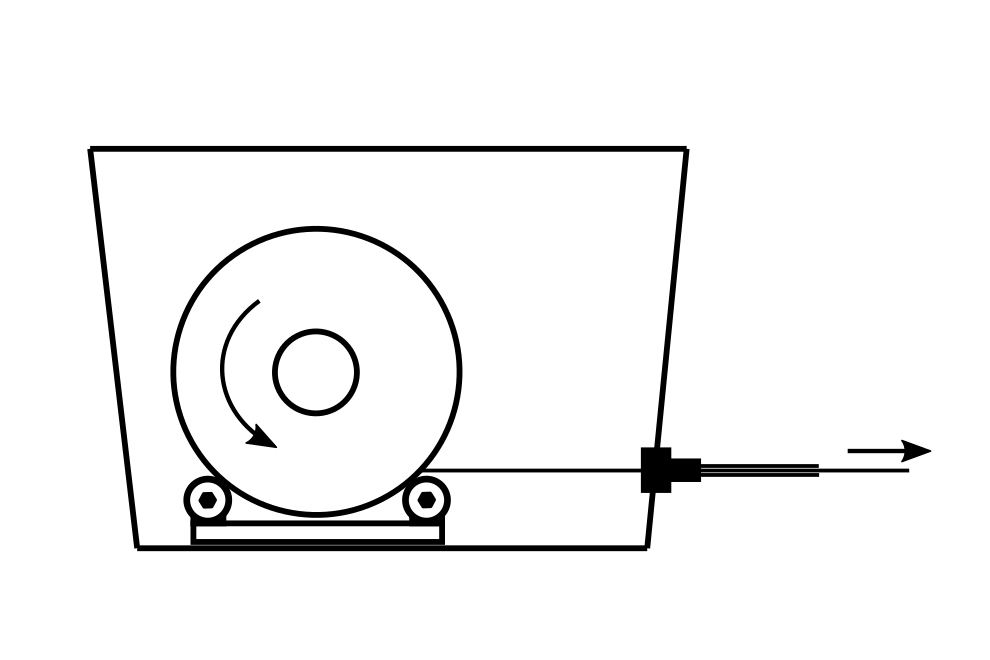

Align the filament spool so that the end of the filament is at the bottom of the filament spool and points towards the filament outlet, see the attached sketch with the correct direction of rotation of the filament spool. Always pull the filament end off the filament spool from below, as parallel as possible to the bottom of the box and thread it straight into the outlet.

Push the filament through the PTFE tube until the filament end protrudes out of the tube at the front.

At the end of the PTFE tube, leave 1-2 cm of filament protruding, in order to then put on the plug or insert the tube into the plug fixed at the fialment box until it sits well and firmly.

When inserting the filament spools, check that they can rotate freely and that they do not touch the floor or the walls of the storage box – if a filament spool scrapes or blocks, this spool is not suitable for the filament storage box.

Check if the filament is threaded into the outlet parallel to the floor and as straight as possible, and that nothing is preventing the filament from being pulled out. Also check the correct direction of rotation of the filament spool and correct it if necessary.

Check whether filament has become tangled on the filament spool – if necessary untangle and rewind.

If the filament blocks or can only be pushed through the outlet under a lot of pressure, the outlet and the PTFE tube must be checked for blockages or too small bore diameters and cleaned or replaced.

Check the ease of movement of the pulleys and the condition of ball bearings at regular intervals (every month).

Always perform a safety check on the filament box before 3D printing

Perform the following safety check before 3D printing!

- Check whether the filament spool is stable on all four single pulleys, or on the two wide pulleys respectively.

- Check whether filament has become tangled on the filament spool – if necessary untangle and rewind.

- Check whether the selected filament spool can rotate freely and is not in contact with other spools.

- Check that the filament spool holder is parallel to the wall of the filament storage box and that the filament spools do not touch the walls of the storage box.

- Check the filament feedthroughs and PTFE tubes for blockages and whether the filament can be easily pulled through and check that the filament runs smoothly.

- If a long PTFE tube is used up to the 3D printer, then make sure before printing that it cannot be pulled or squeezed into the extruder or the mechanics of the 3D printer.

- Check whether the silica gel bag or the silica gel holder is blocking or touching the filament or the filament spool.

If one of the points listed is not correct, do not start the printing process but fix the error first.

Maintenance of the desiccant (silica gel):

Check the color of the silica gel (desiccant) at regular intervals (1-2 weeks) – if the saturation of the silica gel is reached very quickly (less than 4 weeks), the box may be leaking.

When saturation is reached (discoloration of the indicator dye) regenerate the silica gel bag according to its instructions.

Normally the selected silica gel bags (for 100 ml water absorption) last about 3 to 6 months until it is saturated and has then to be regenerated according to its instructions.

Do not leave silica gel granules or bags open in the room for too long – always store them in the closed filament storage box or a closed plastic bag! Also keep the opening of the box to change a filament spool as short as possible, so the desiccant lasts longer without having to be regenerated.

Disclaimer

The instructions and the associated files are an inspiration of Ingenieurbüro Dr. Janko GmbH to build this project yourself. Since Ingenieurbüro Dr. Janko GmbH has no way of checking and influencing the required quality of the printed components and purchased parts as well as the quality of the assembly and the correct functioning of the project or if any inadmissible changes and modifications to the project has been made, Ingenieurbüro Dr. Janko GmbH accepts no liability for functionality, stability or the damage incurred by the project.

0 Comments