The new filament box is here

Save time, filament and purchased parts!

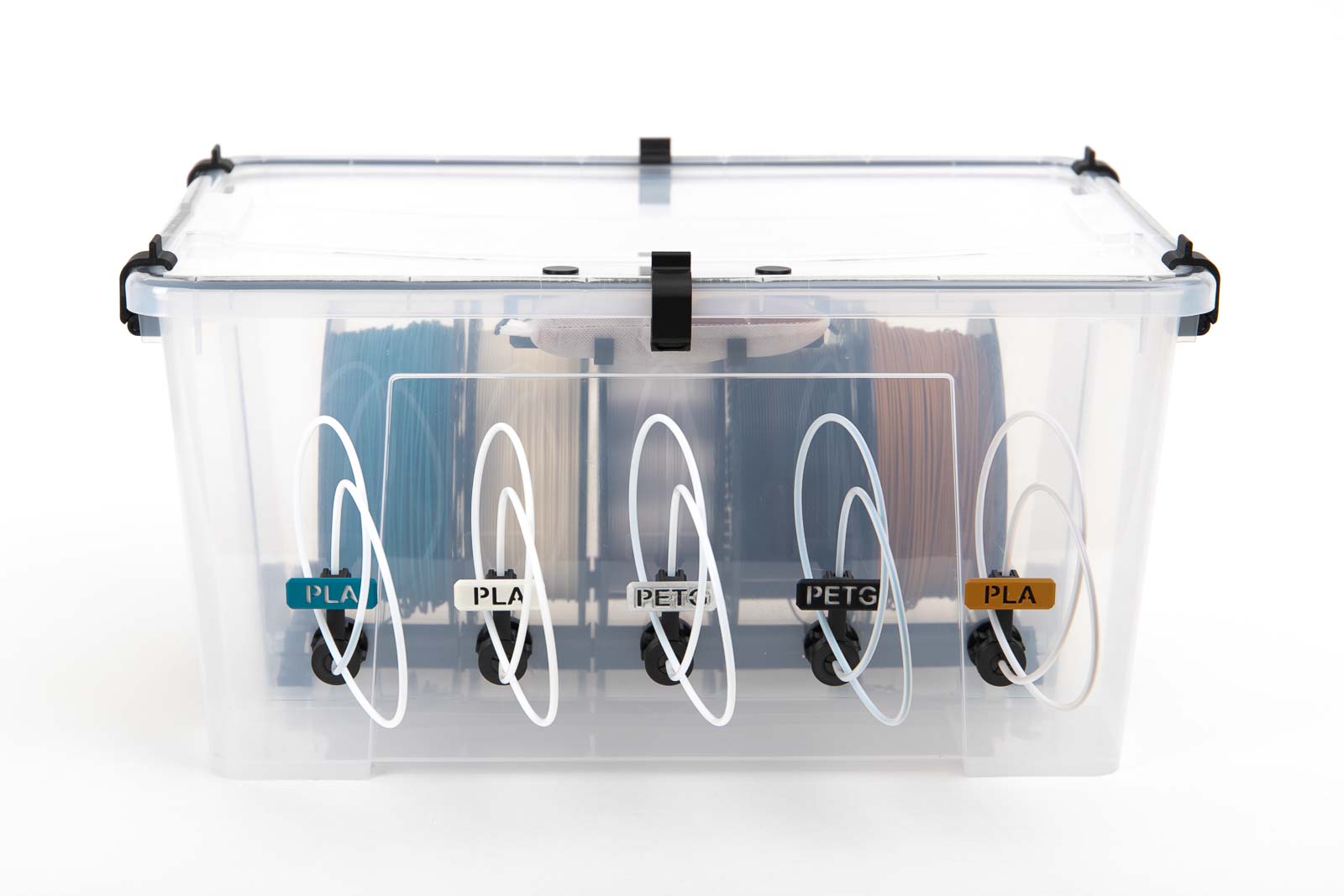

The first version of the filament box was created four years ago and is getting a little old. Over the past few years I have continuously developed the design, accompanied by the thousands of operating hours of my now five filament dry boxes.

After the ANYBOX V2, there is now the third revised and improved version of the DIY filament dry box: the ANYBOX Version 2023!

It can be found alongside many other 3D printing projects here on my new website 3D-PRINT-FILES.

You can find the instructions for building the new box here:

- Possibility to use IKEA Samla boxes: Build Ikea Samla Filament Box

- Less purchased and 3D printed parts

- Better guidance of the filament spools

- Extra wide pulleys

- Better use of space in the air-tight box

- PrintFit system for precisely fitting connections

- Faster filament changes

- Easier filament handling

- Less filament waste

- New silica gel desiccant holder

- Silica gel beads box for loose desiccant

The most important improvements of the new filament box

IKEA Samla Boxes

The new version of the filament box contains all 3D printing files to modify inexpensive 6 gallon (22 liter) or 12 gallon (45 liter) IKEA Samla boxes to make them airtight and use them as a filament box.

Link to the conversion instructions: Build Ikea Samla Filament Box

IKEA Samla box 6 gallon (22 liter)

IKEA Samla box 12 gallon (45 liter)

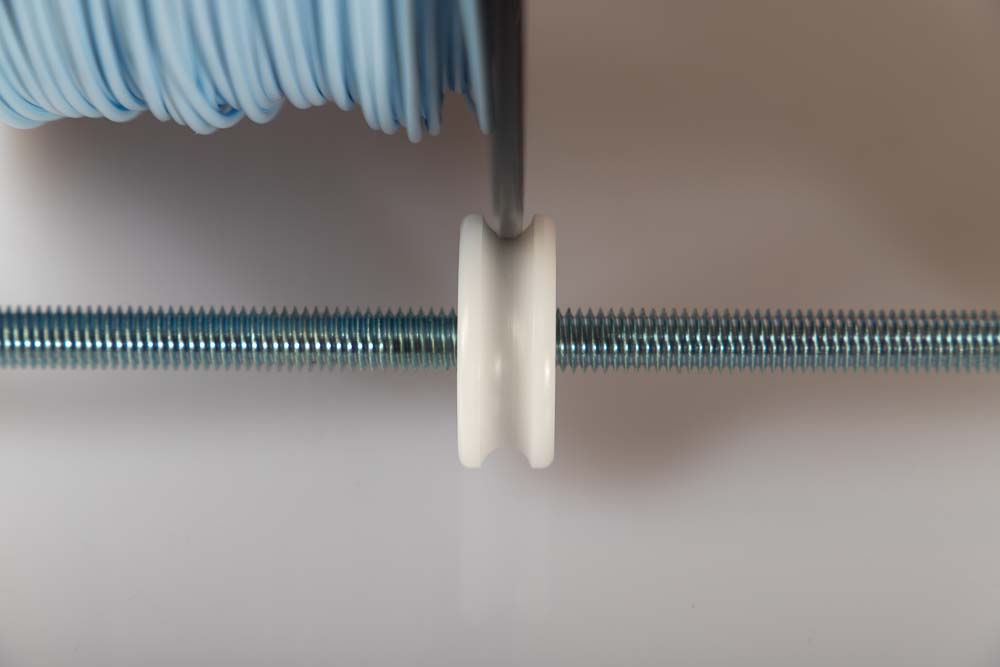

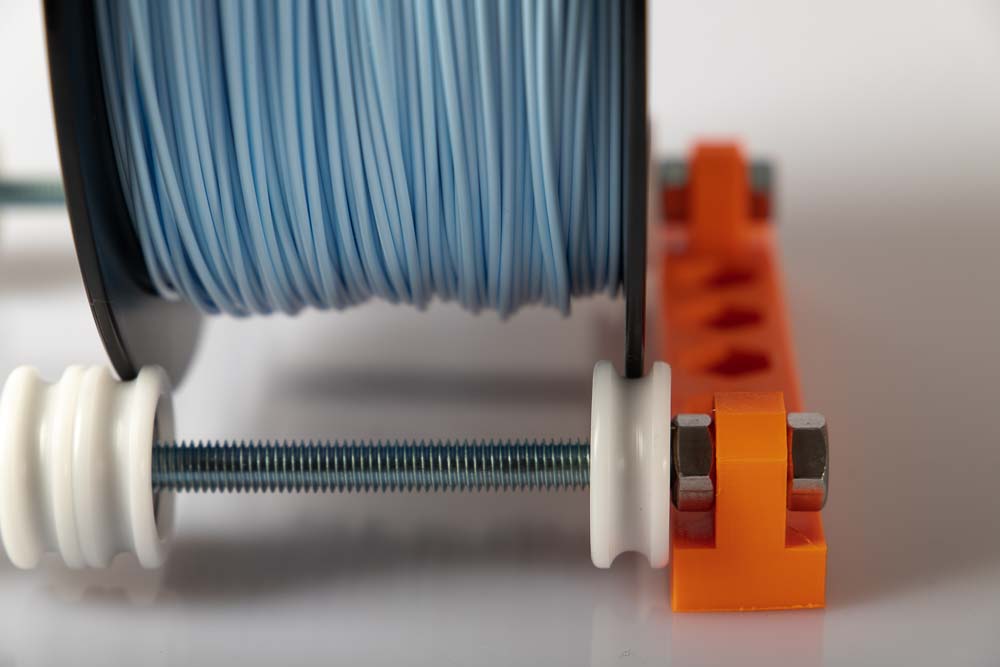

New pulleys

Inserting filament spools was sometimes difficult with the first version due to the narrow guide of the purchased pulleys. With the new filament box version, only commercially available ball bearings + 3D printed pulleys are used instead. As a result, the contact surfaces are wider and inserting the filament spools is now much easier.

OLD

NEW

Better use of space

OLD

NEW

Wide pulleys

Another innovation in the 2023 Version is the possibility of using wide pulleys for filament storage. Simply choose from 6 different widths and print. This means that each filament spool stands on only two wide pulleys.

NEW

NEW

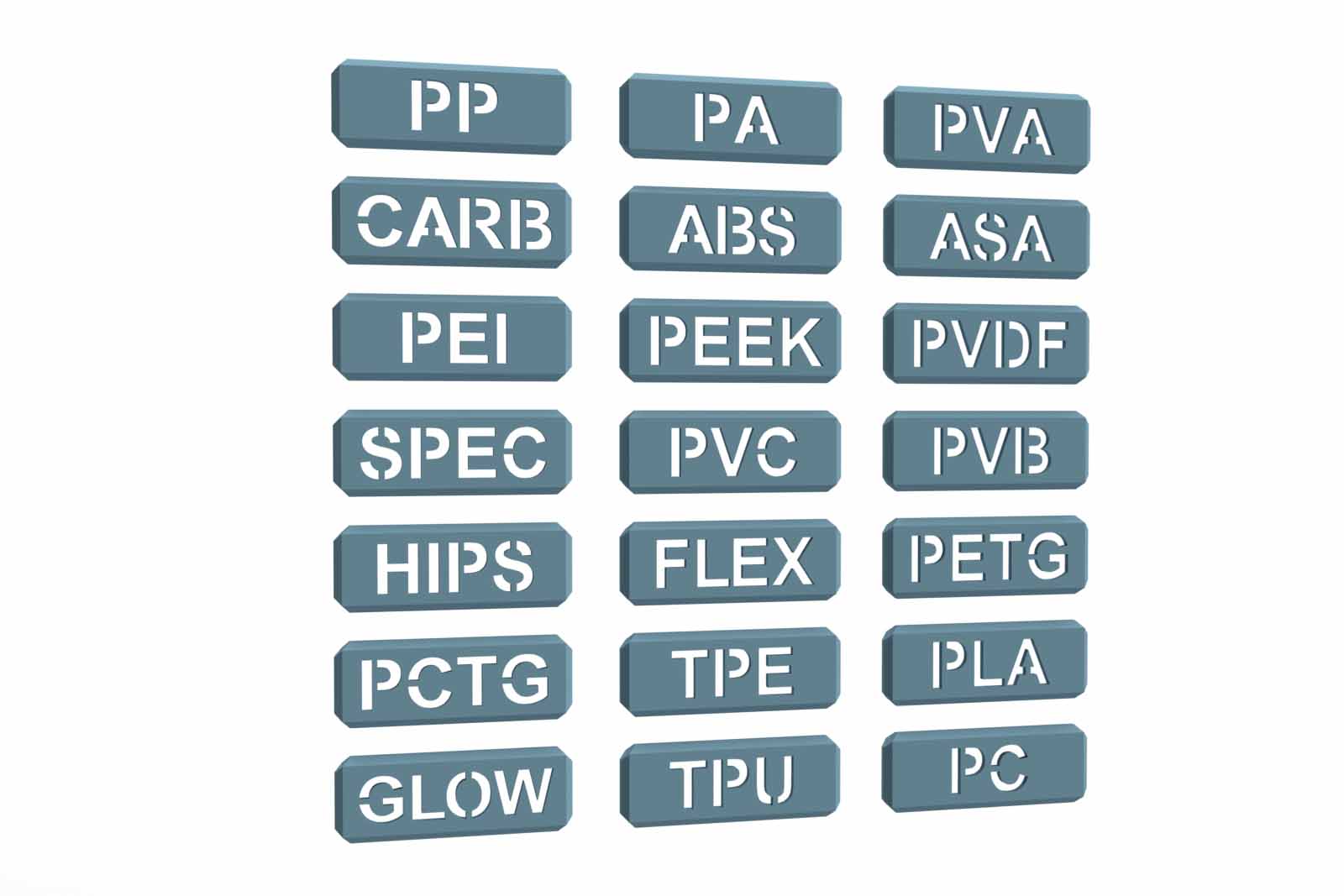

Material type labels

Now optional filament labels can be 3D printed and attached to the filament outlets. This makes handling much easier once a few filament boxes have been built and are in operation 🙂

The STL files are available for 21 different material types.

NEW

NEW

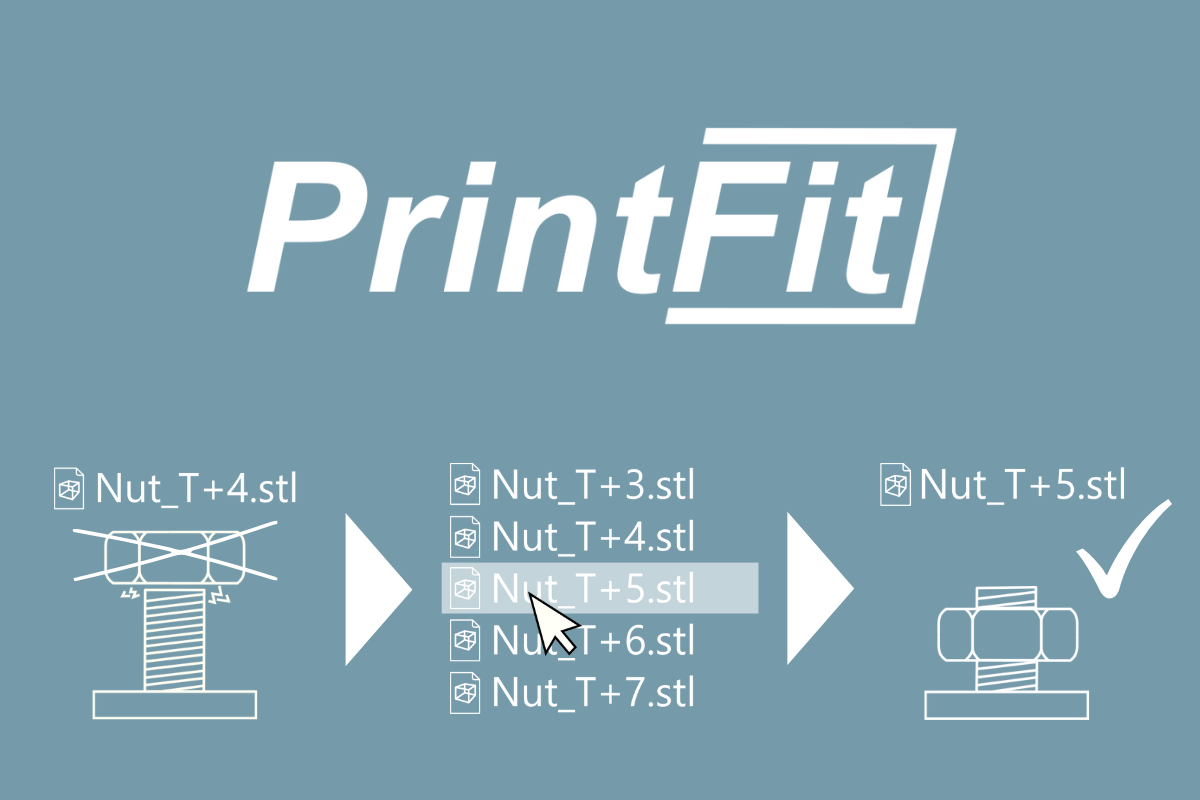

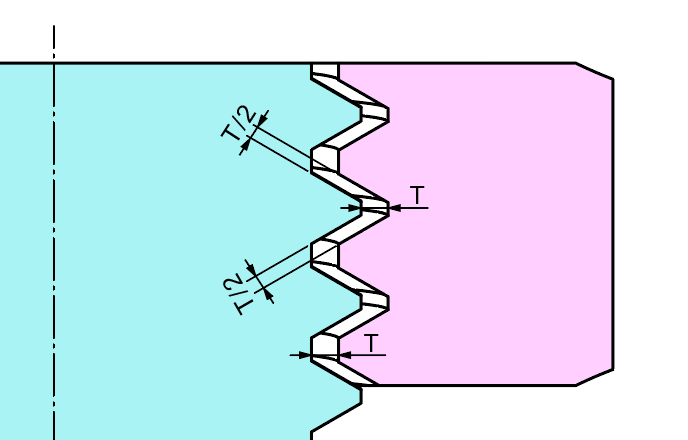

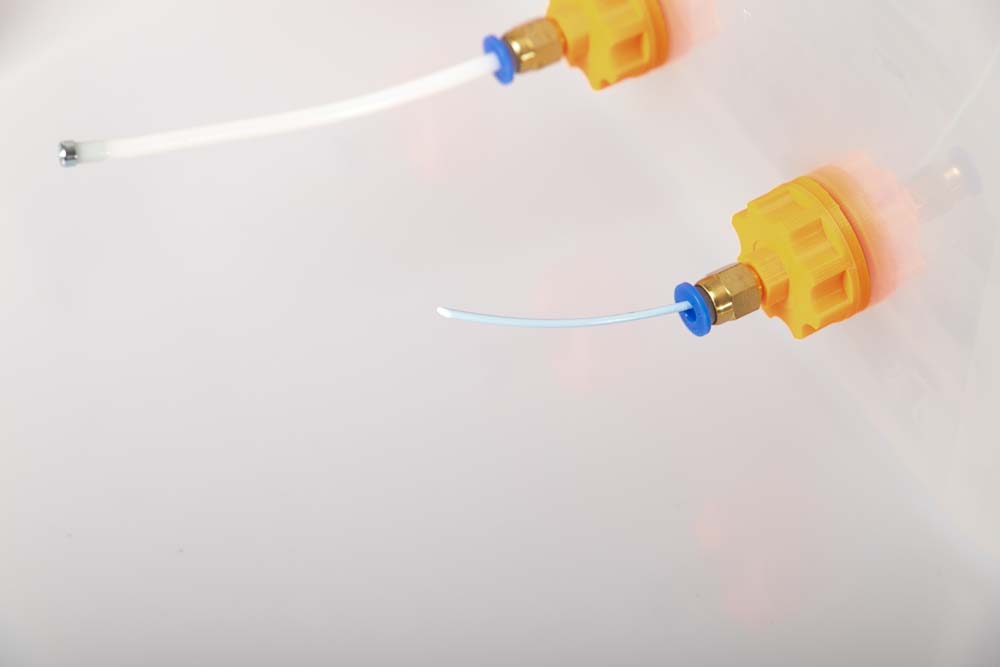

PrintFit System

The 3D print files for critical 3D printing parts such as nuts and bushings for tubes are available in five different sizes. If a connection doesn’t fit, a part can be printed with a larger or smaller diameter. This means that assembly problems and difficult scaling in the slicer are a thing of the past.

NEW

NEW

Less purchased parts

OLD

NEW

Saving of seals and 3D printed parts

The unnecessary inclination of the 3D printed fittings mounts has been omitted in the new version. Due to the now straight end surface, the filament outlets seals much better with the box. Therefore, the printed seals or the silicone for sealing of the old version are no longer needed for the new filament box. This saves three components per filament outlet (seal, washer and pneumatic coupling). The new silica gel holder also no longer requires M3 screws, which saves an additional four screws as purchased parts.

Taken from the entire box, there are a total of 22 parts less in the new version.

OLD

NEW

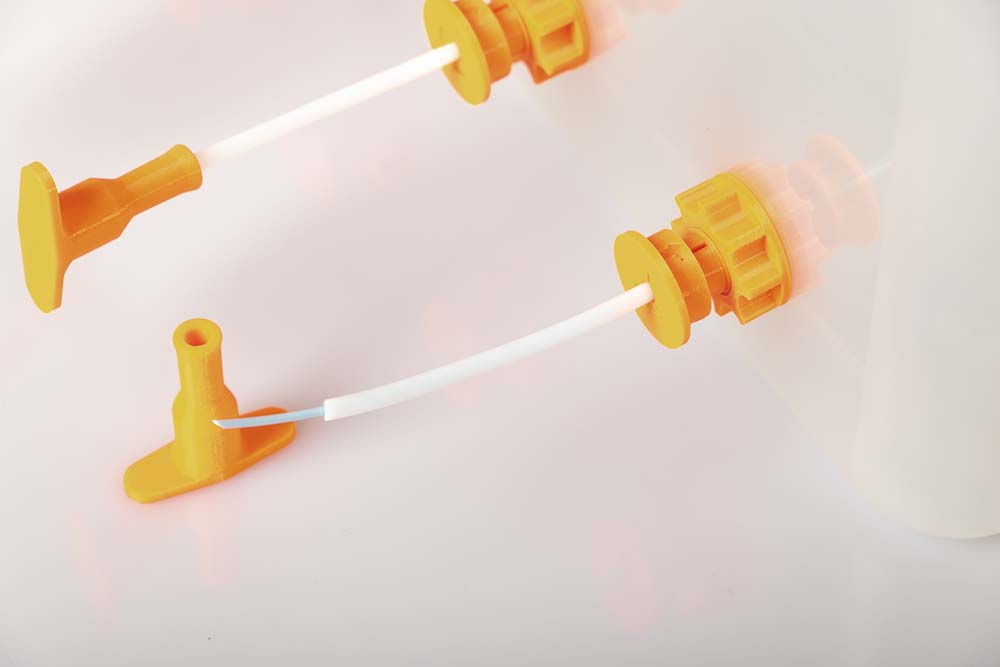

Easy filament handling

– The plug can be pulled and put onto the PTFE tube much easier than it was possible with the pneumatic fitting.

– Thanks to this type of sealing system, very long PTFE tubes can also be used – right up to your 3D printer. This means that much less residual filament has to be pinched off when changing filament.

– A piece of open PTFE tube does not have to be hooked into the pneumatic coupling in order to optimally guide the filament, because it is already installed by default.

OLD

NEW

Silica gel desiccant storage

OLD

NEW

Free Addon

Free Addon

Press-in tools

Also included

Go to the shop to get more information or to get started right away.