3D Print Files – DIY Filament Box – ANYBOX Version 2023

18,90 € incl. VAT

Get the 3D print files for the filament dry box. With the countless included STL files in the highest resolution, you can print out all the necessary 3D printed parts for the filament box yourself.

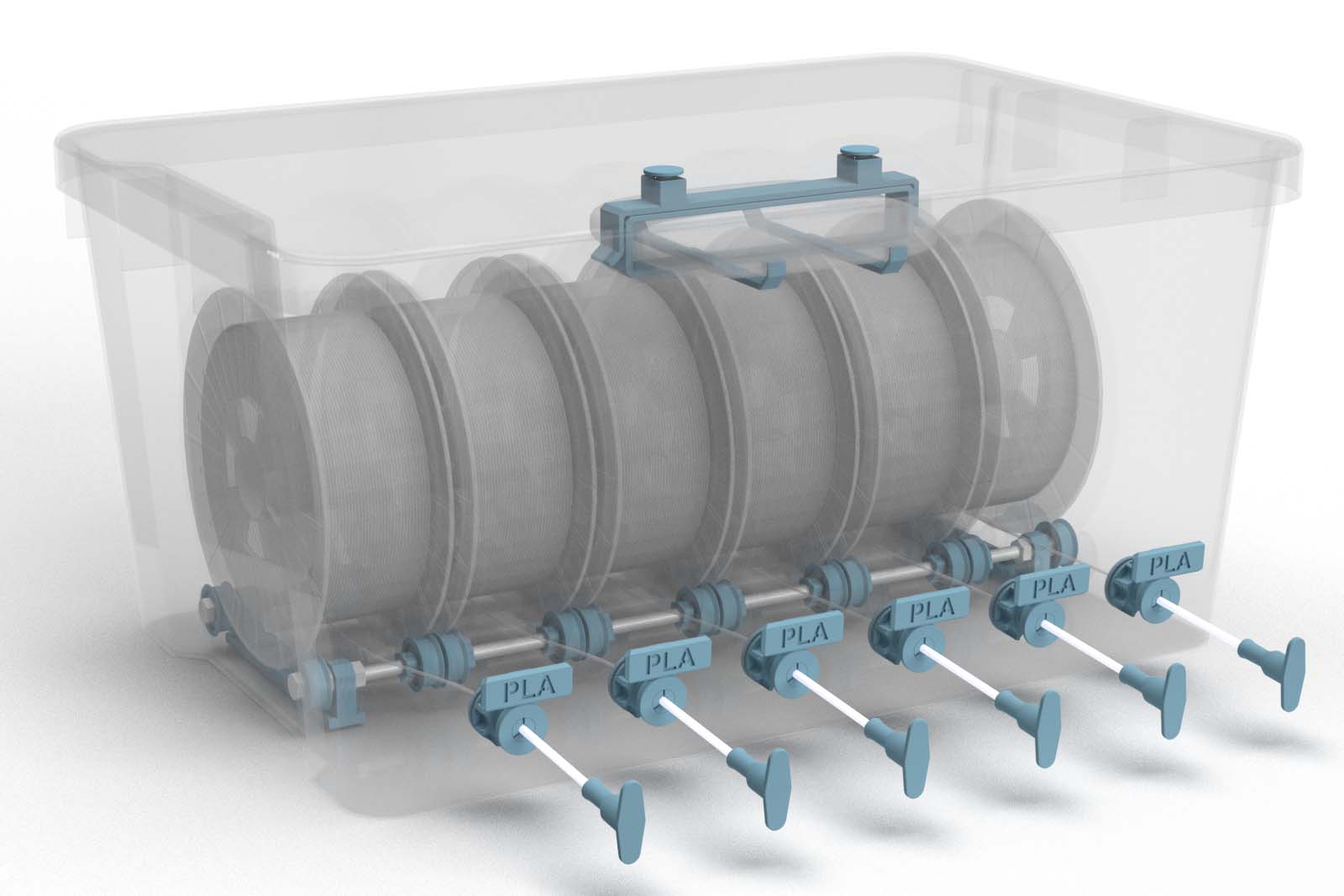

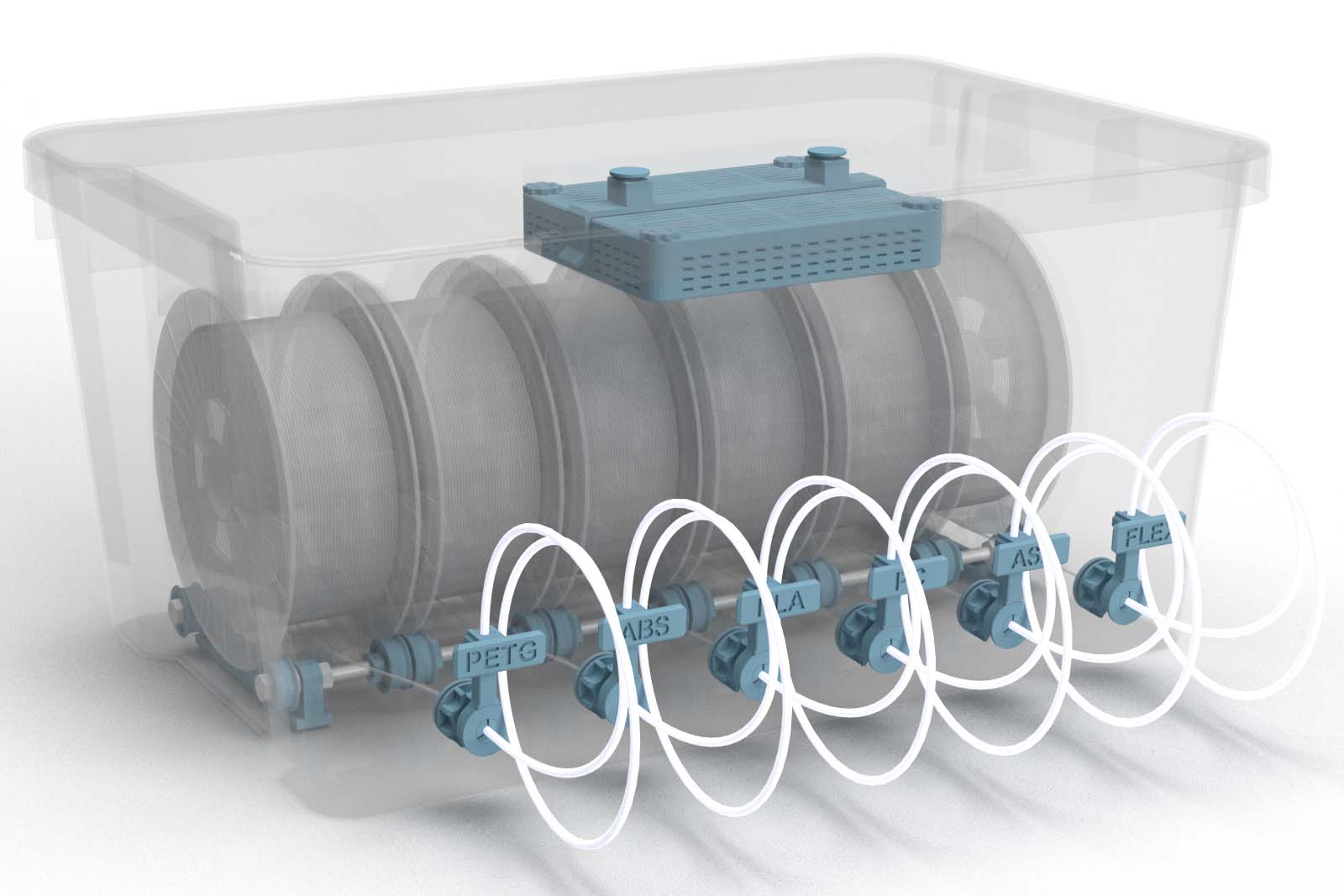

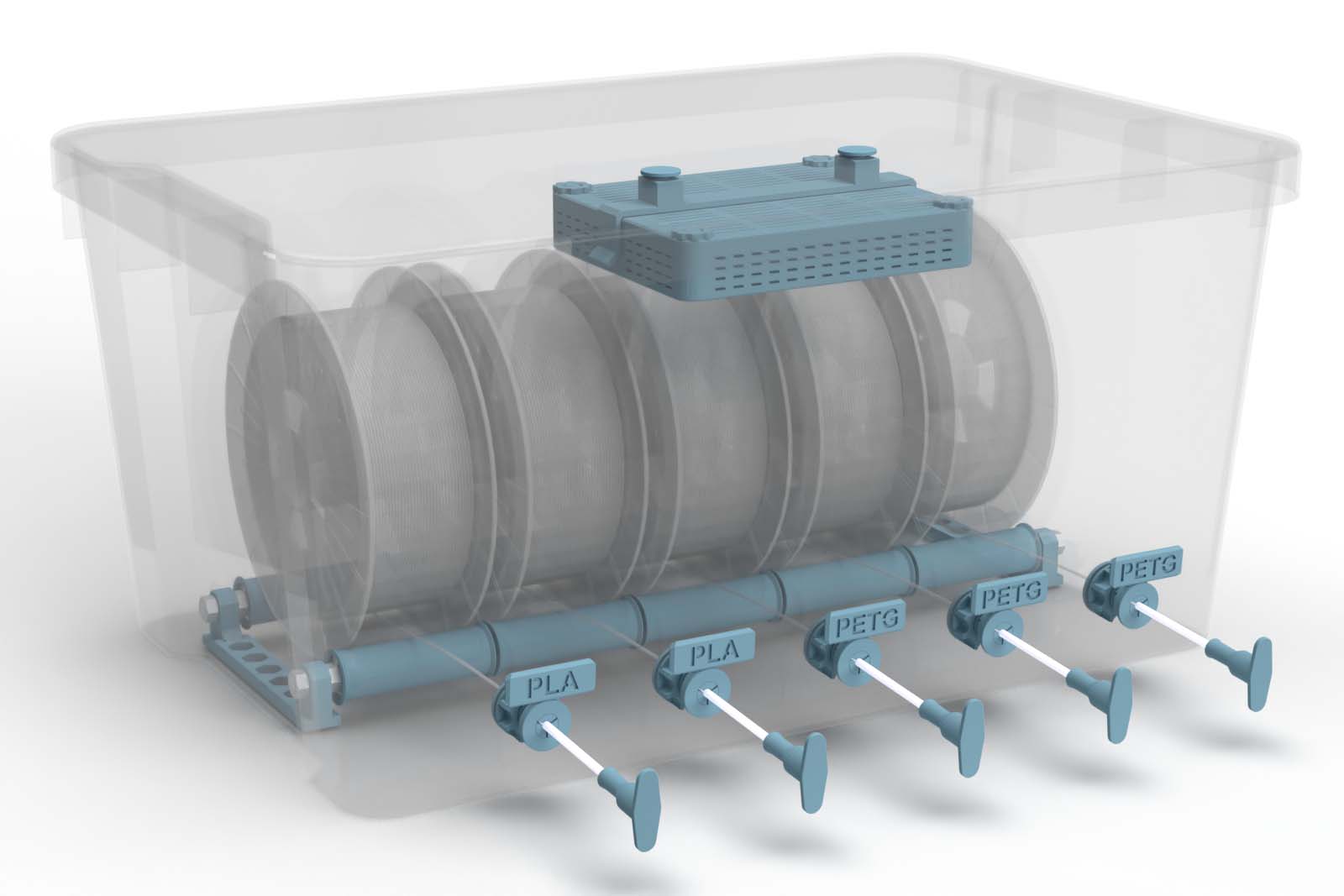

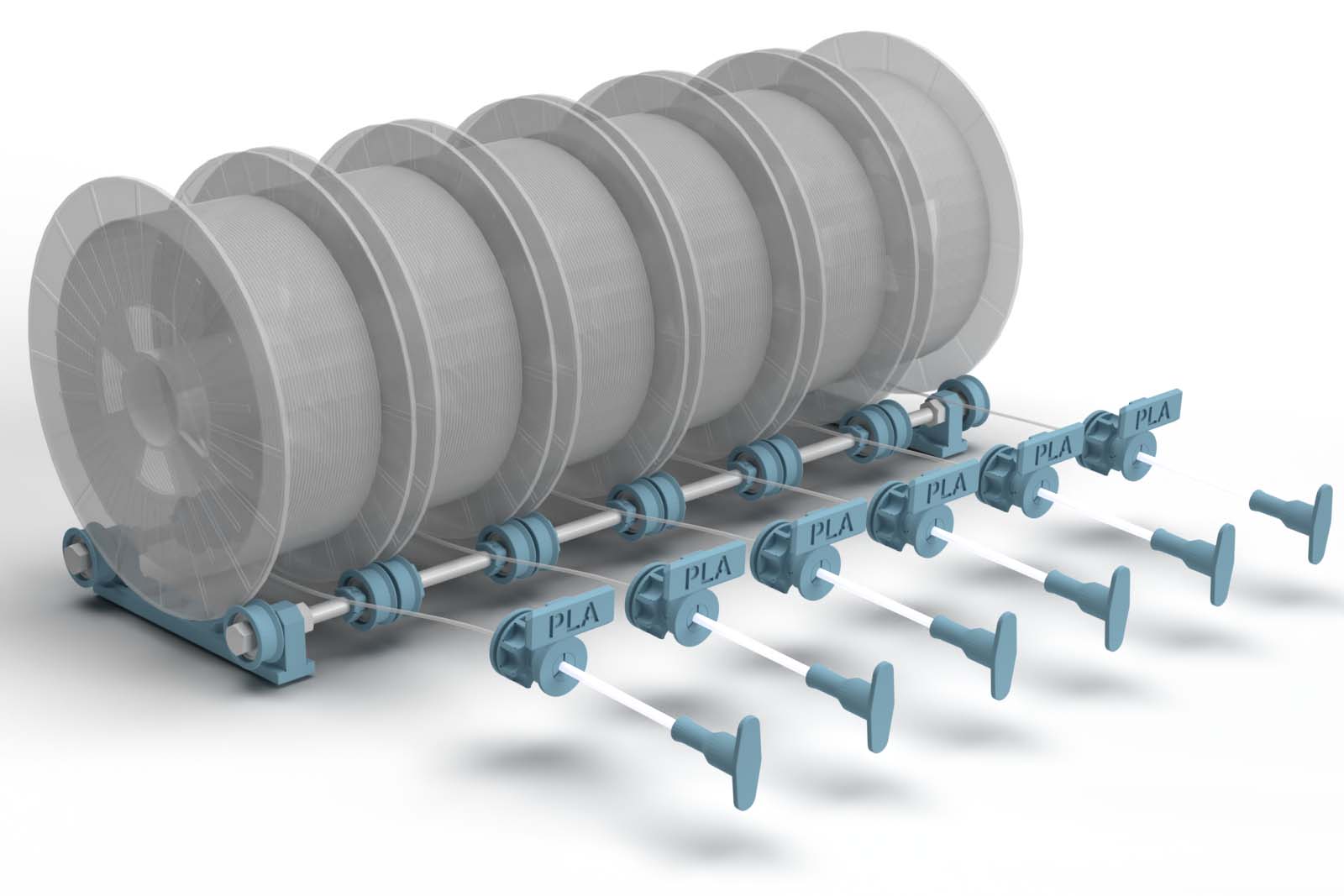

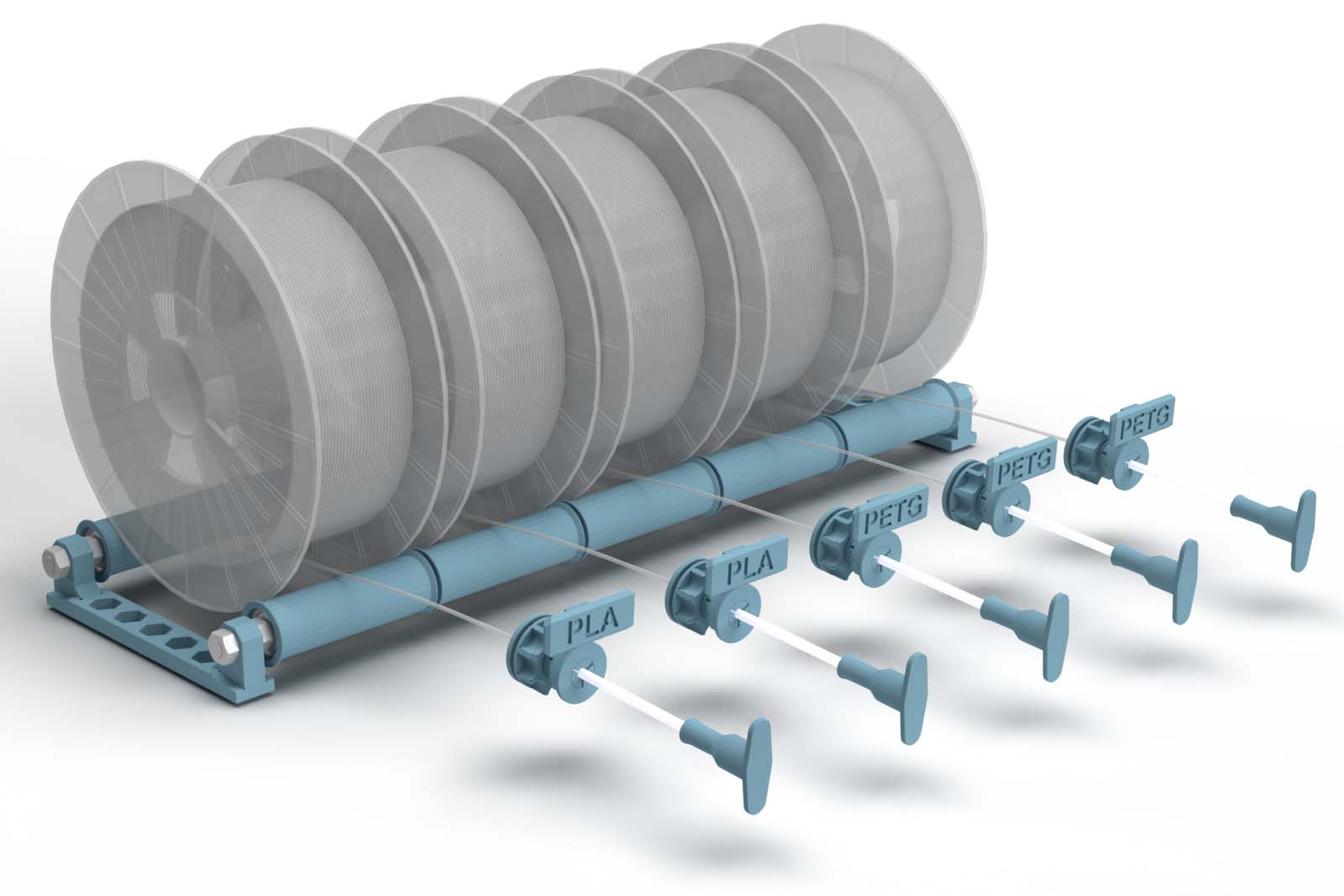

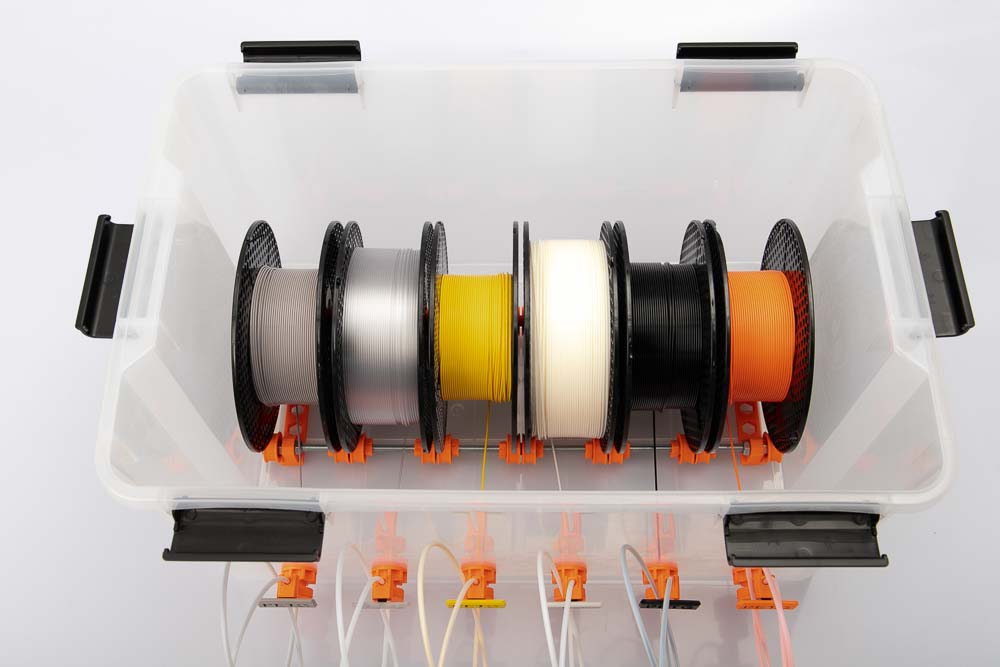

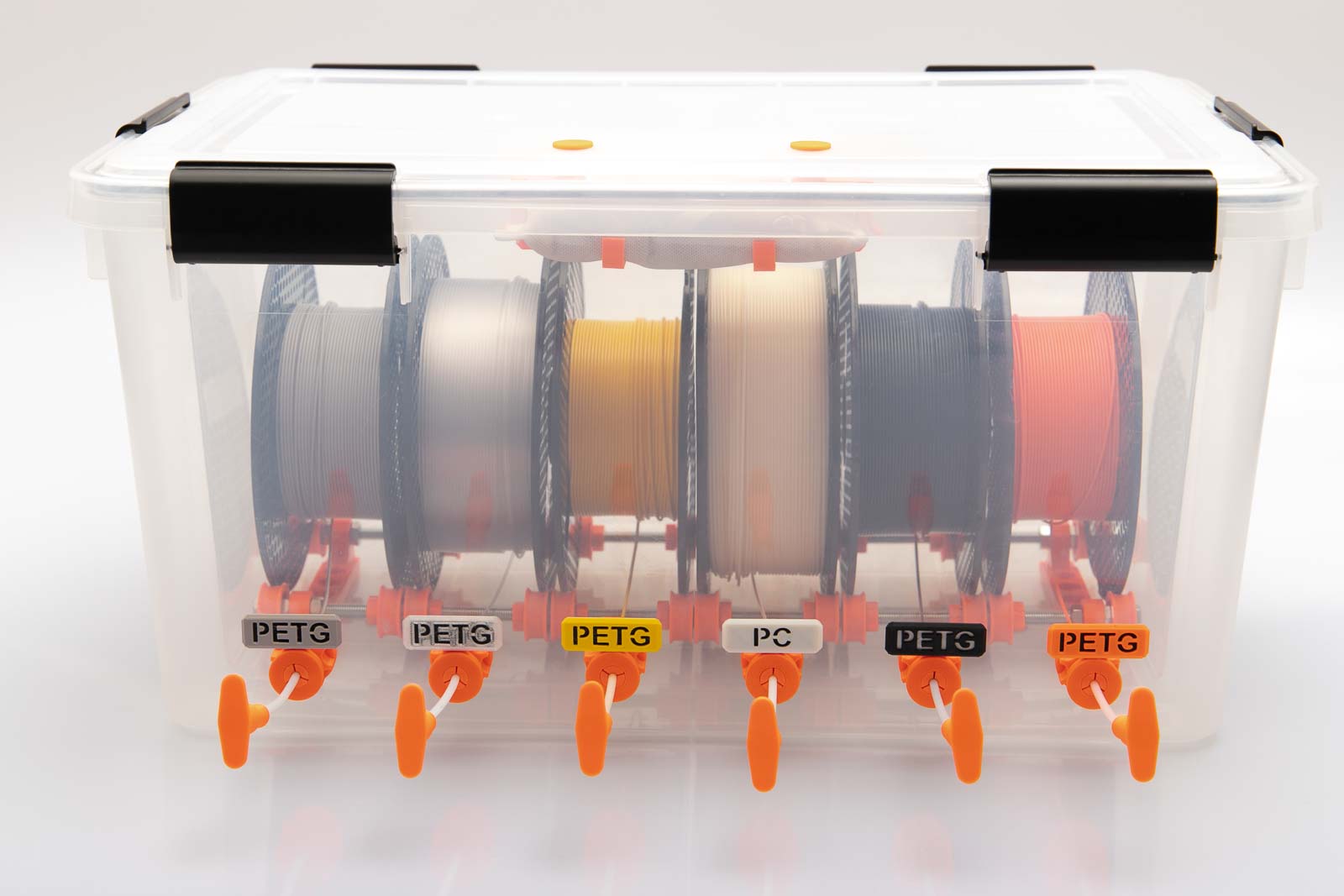

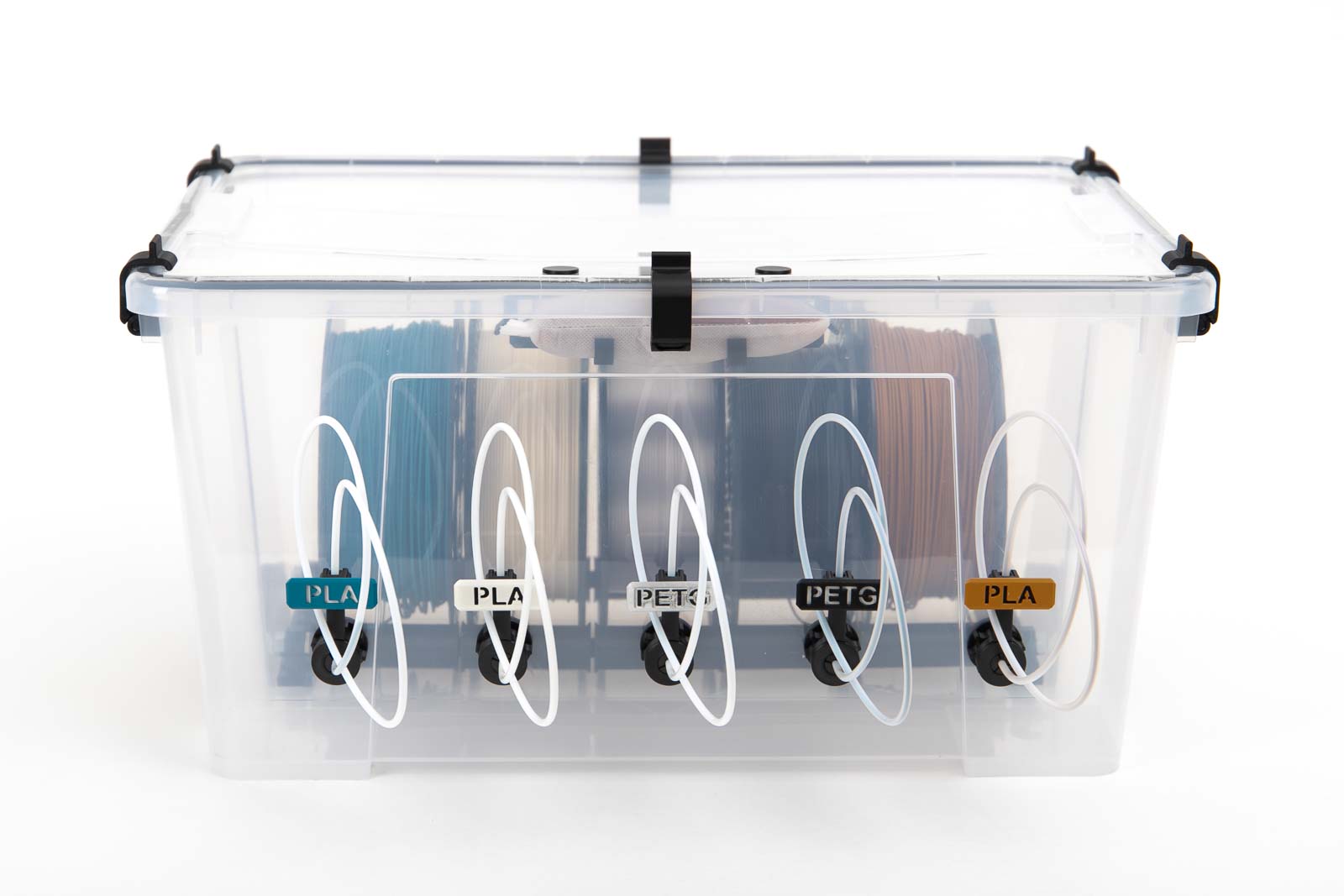

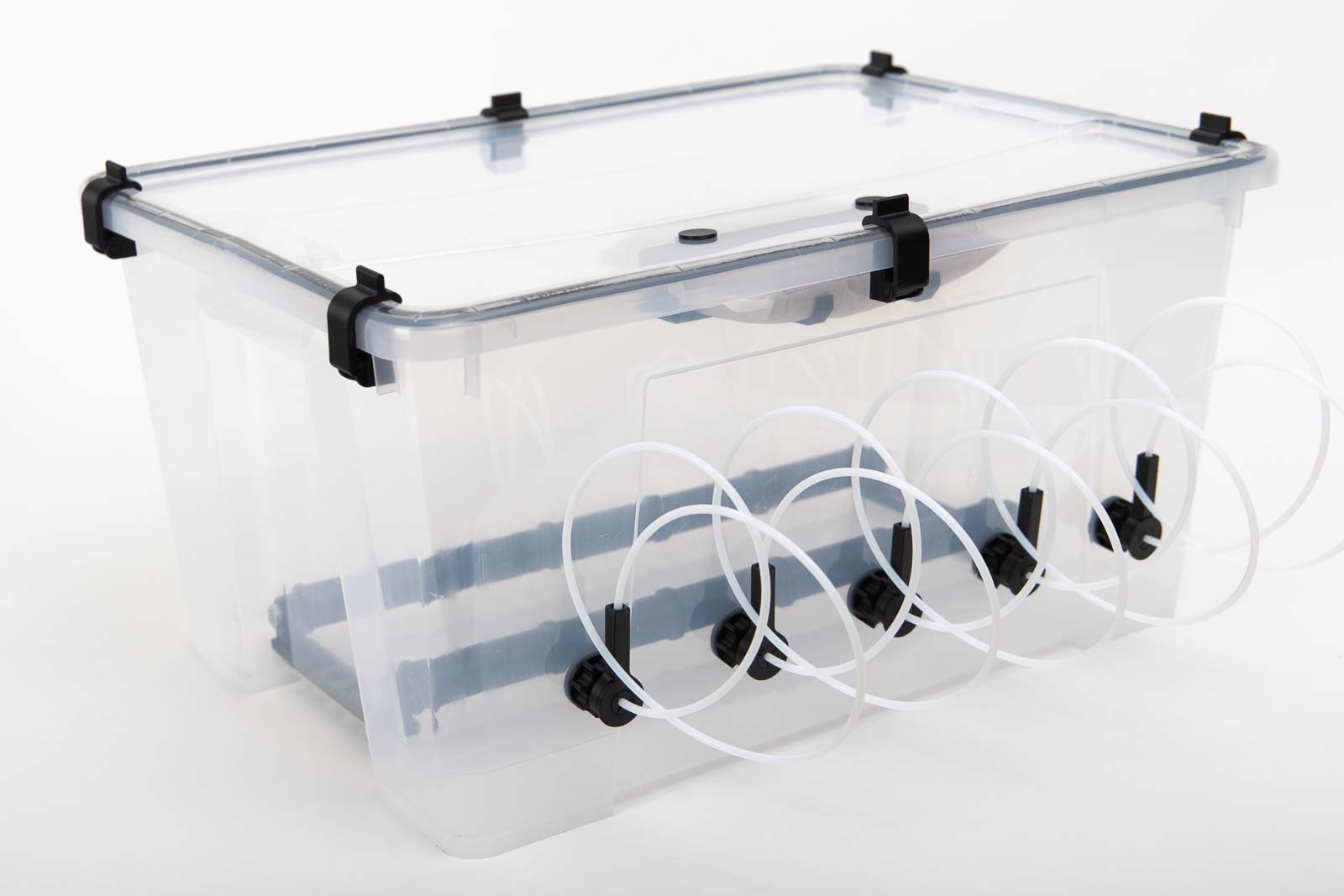

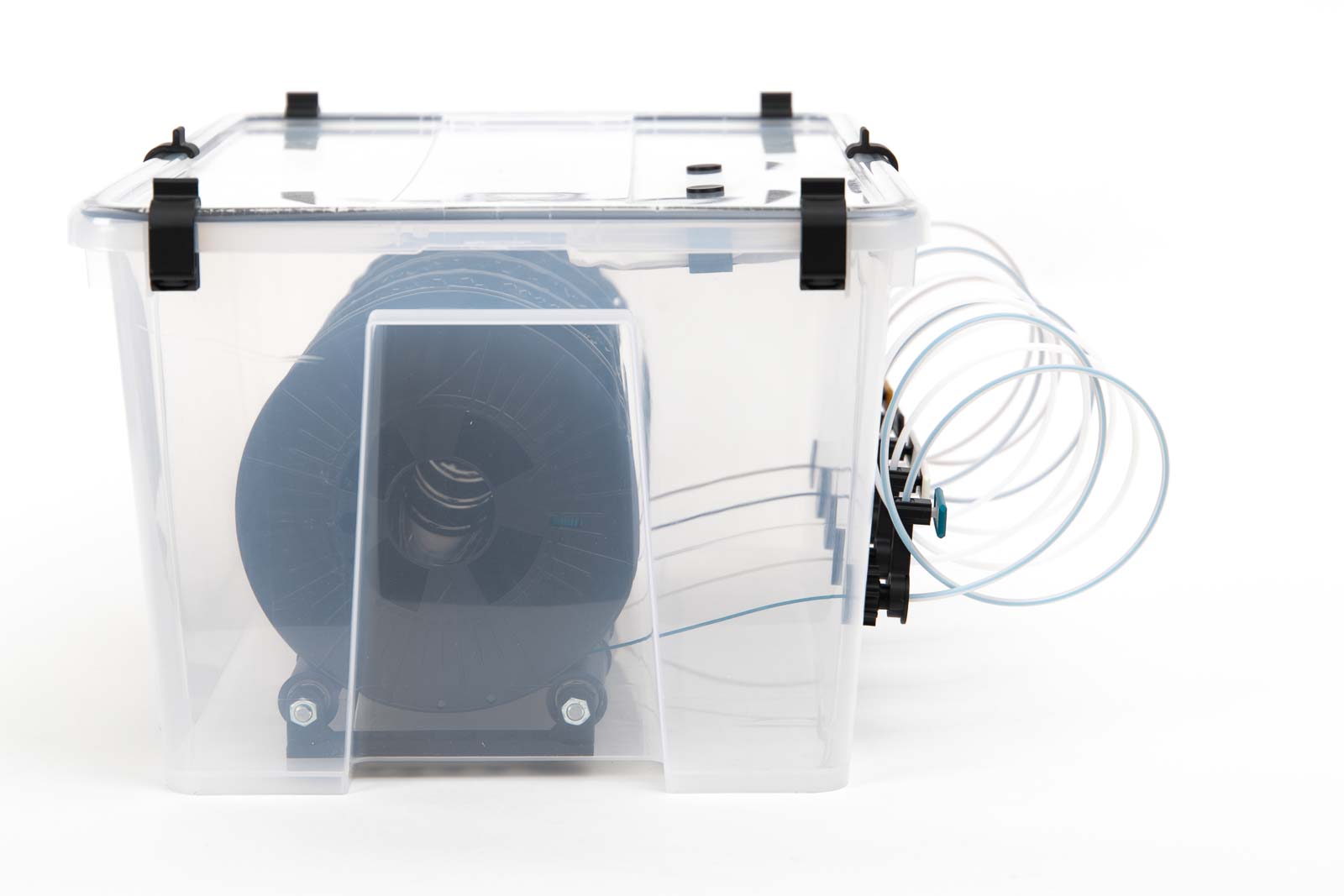

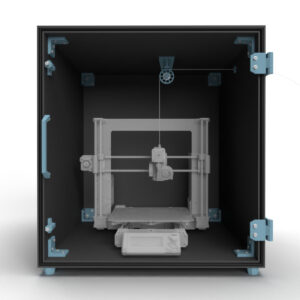

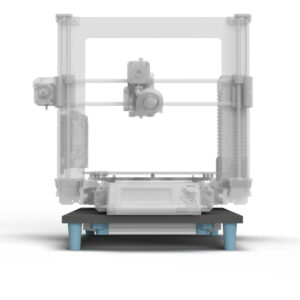

The files are optimized for FDM / FFF 3D printing process and can be printed without support structures. The box is designed for up to 6 spools of filament and always keeps them dry and dust-free. So your favorite filaments are always ready for the next print job without the annoying spool change on the printer.

This product is a digital product, you get the 3D print model files. After the purchase and payment you will receive a download link to the files by email. The 3D printing templates are compressed into a ZIP file as high-resolution STL files. You can find the assembly instructions of the DIY filament dry box here.

You can also use the low-cost IKEA Samla boxes, which can be converted in just a few steps, see the instructions Build Ikea Samla Filament Box.

All models are optimized for FDM / FFF 3D printers and do not require any support structures for printing.

Please note that in addition to the 3D print files, purchased parts (air-tight box, screws, nuts, silica gel, etc.) are required. You can find a list of all the parts you need in the bill of materials in the filament box instructions.

Parts of this 3D printing project have to withstand some mechanical load, so therefore a PETG, ABS, ASA or a similar mechanically resistant filament is recommended. PLA is not recommended due to the more brittle nature of this material and the lower layer adhesion.

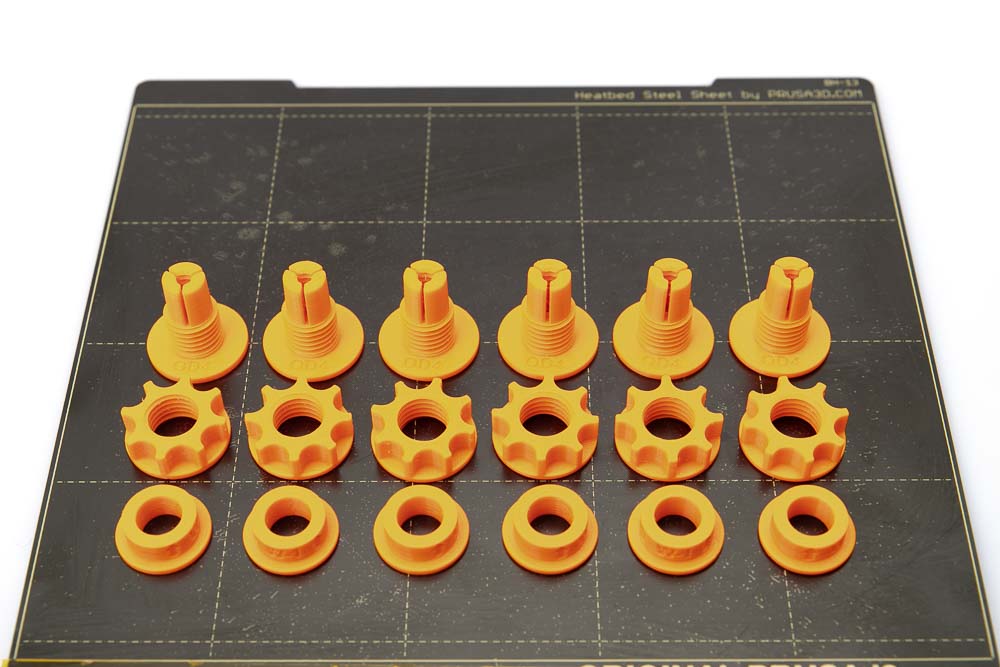

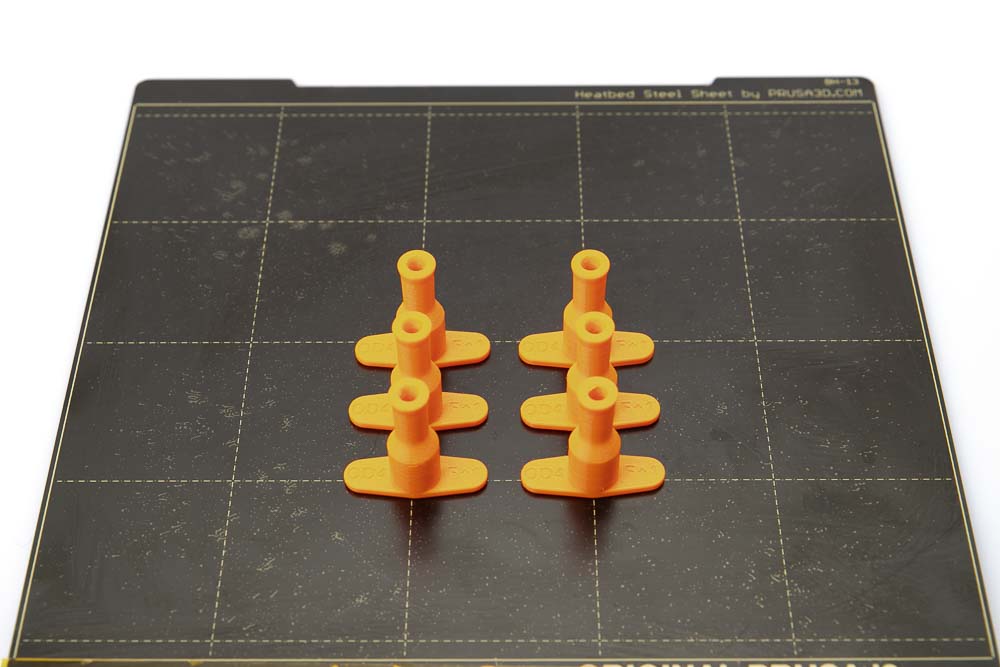

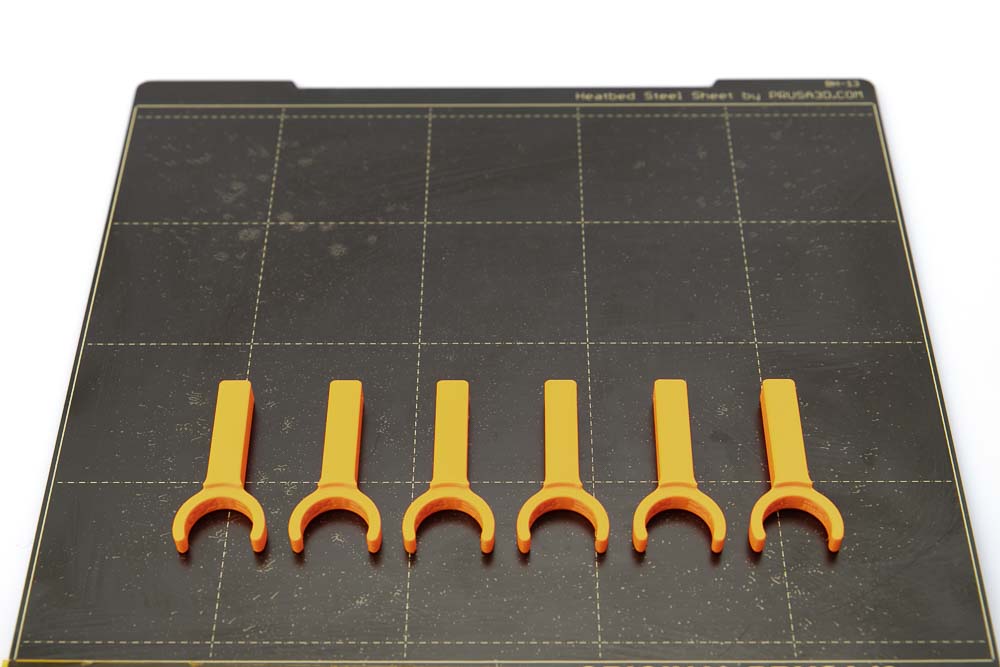

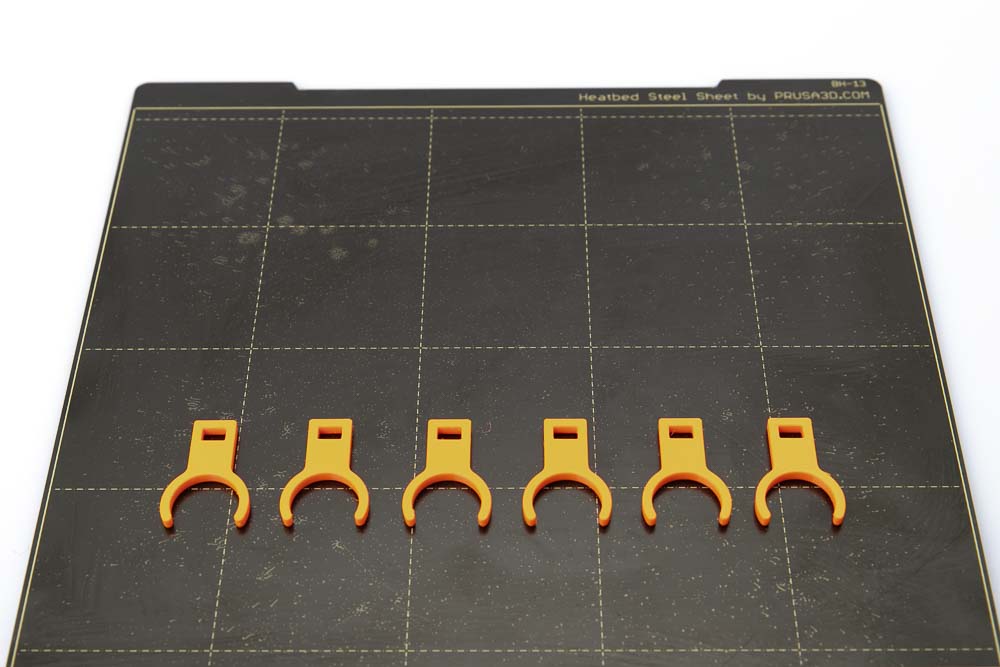

The following STL files in the highest resolution are included:

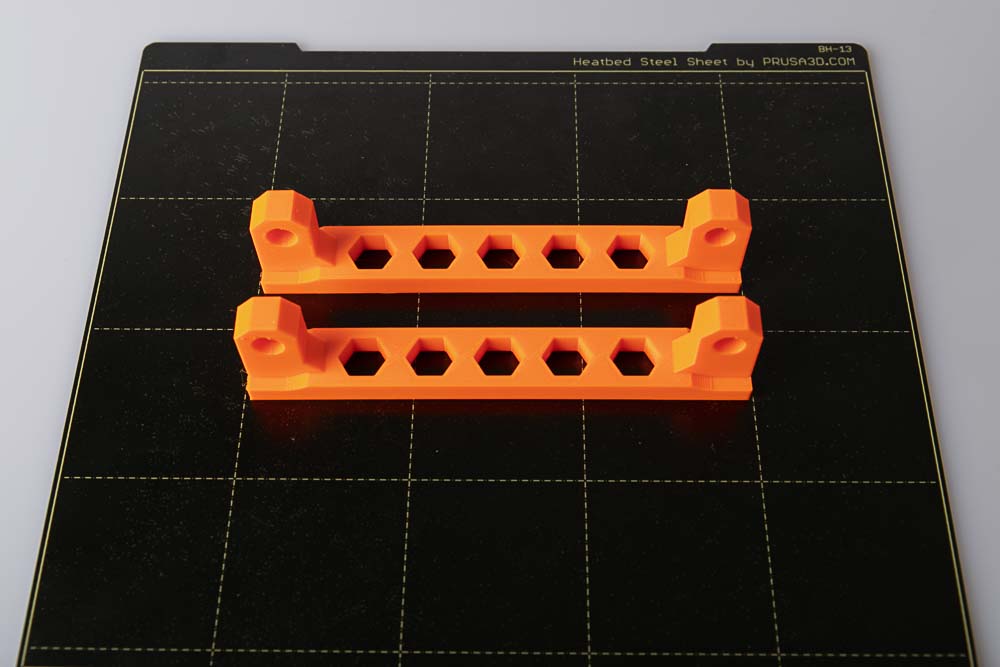

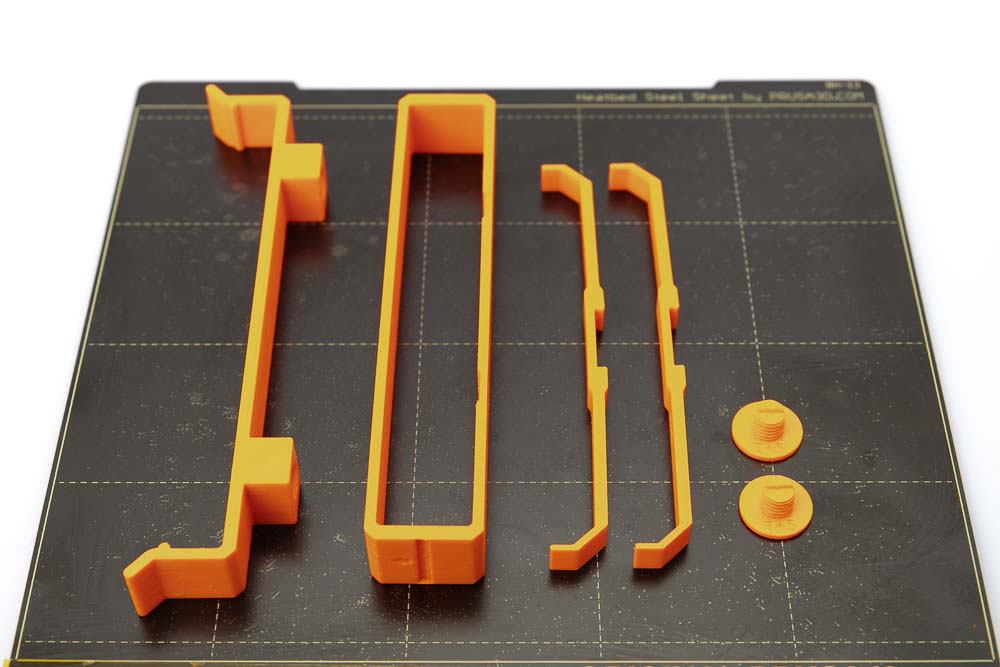

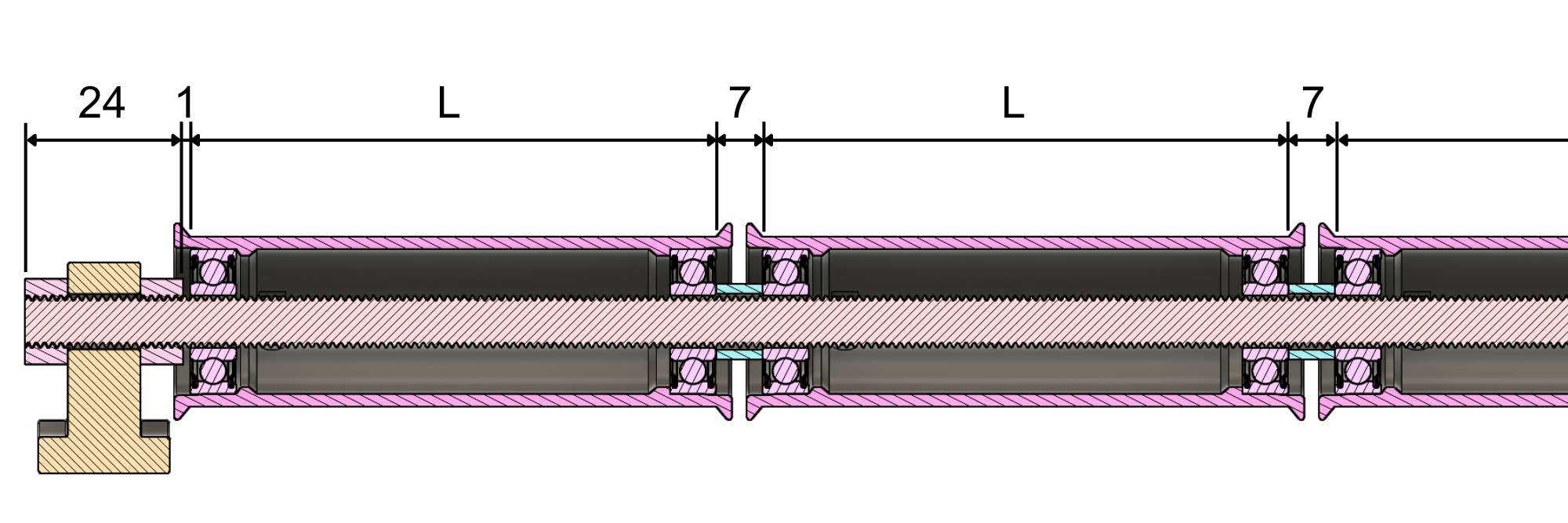

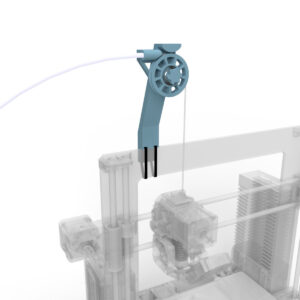

- 006100_Rod_Mount

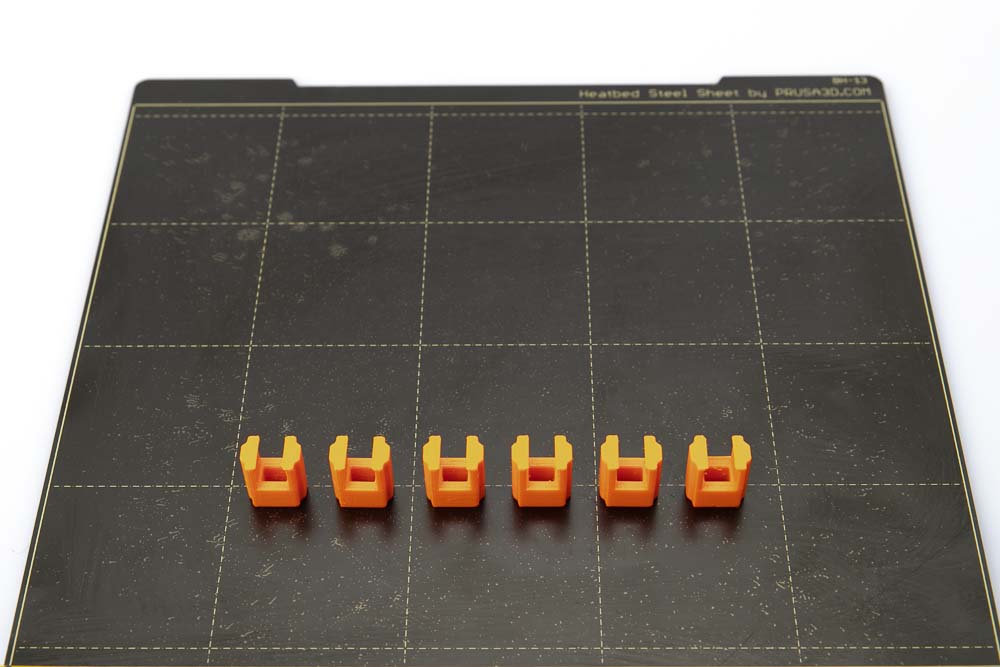

- 006200_Pulley_F## (PrintFit)

- 006220_Pulley_Wide_L##_F## (PrintFit)

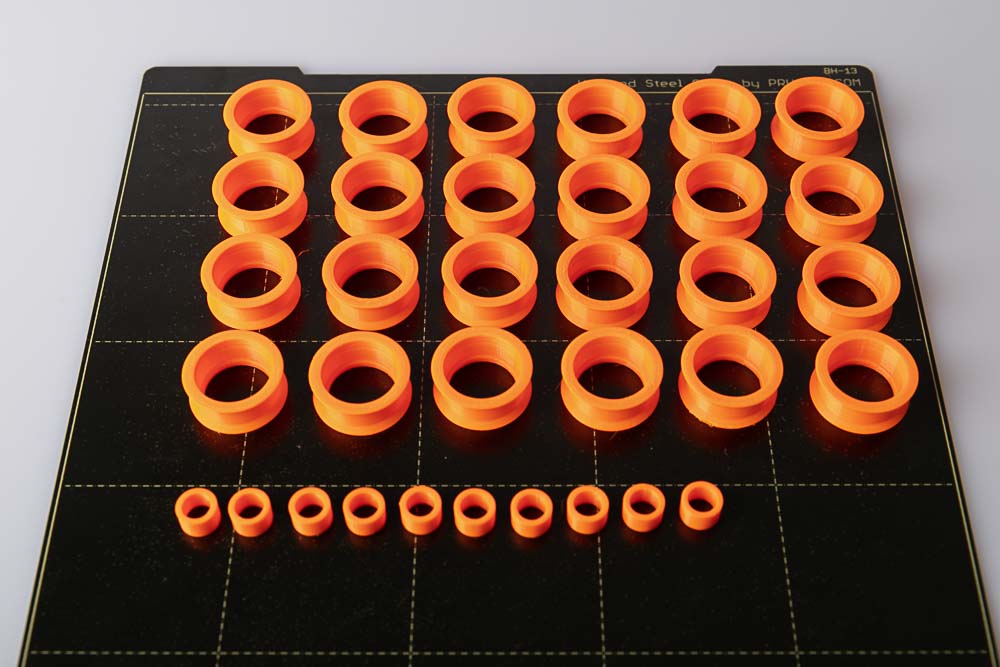

- 006300_Spacer

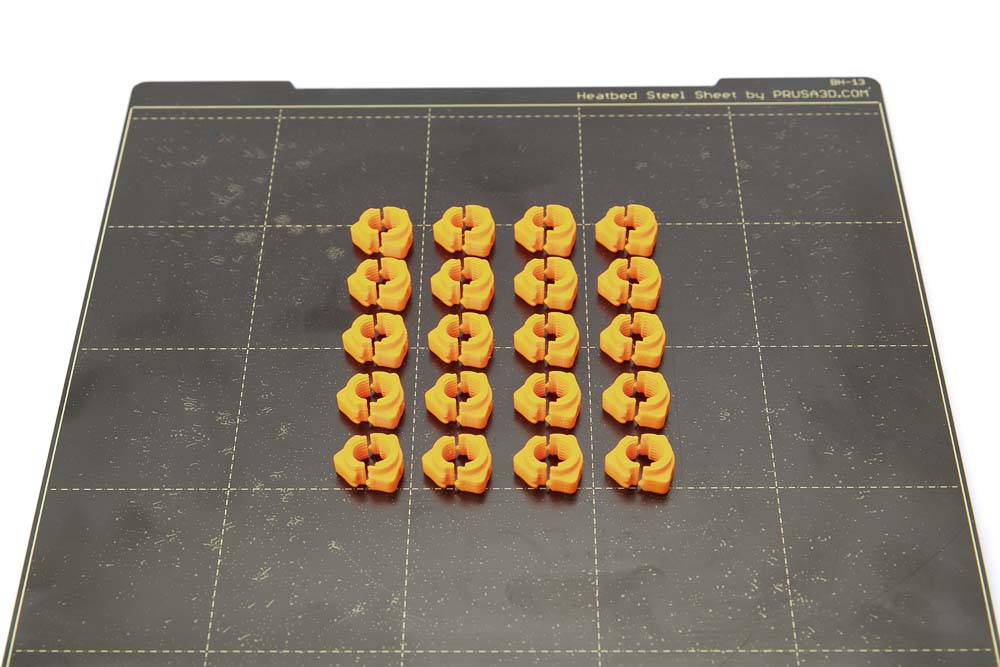

- 006400_Quick_Lock_Nut_T## (PrintFit)

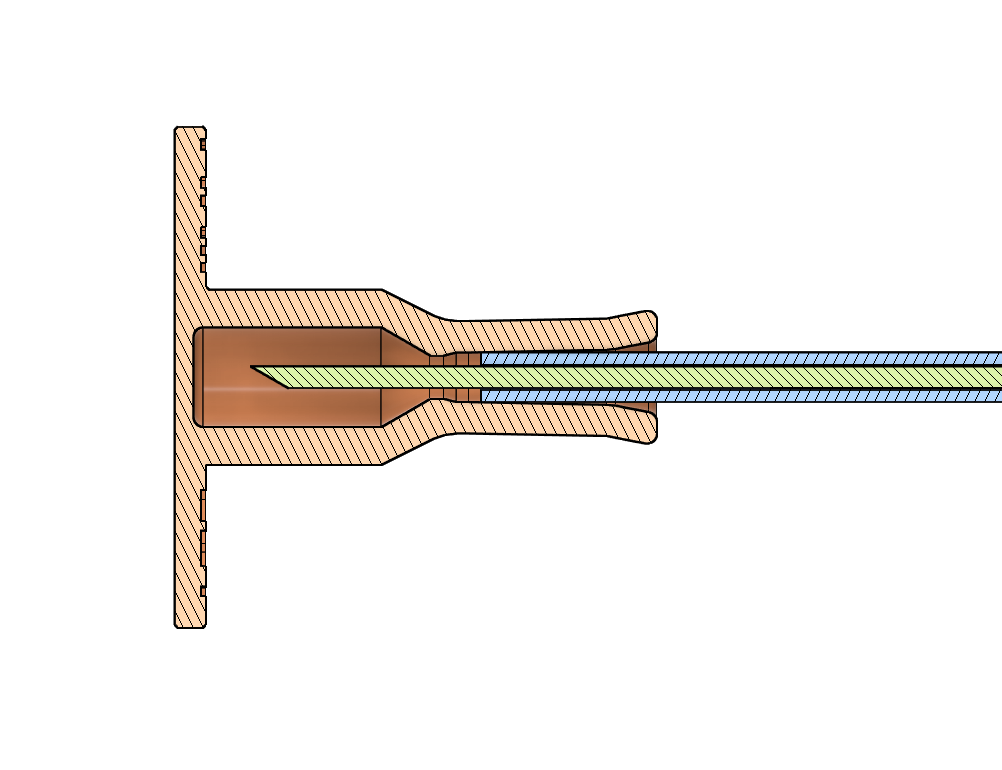

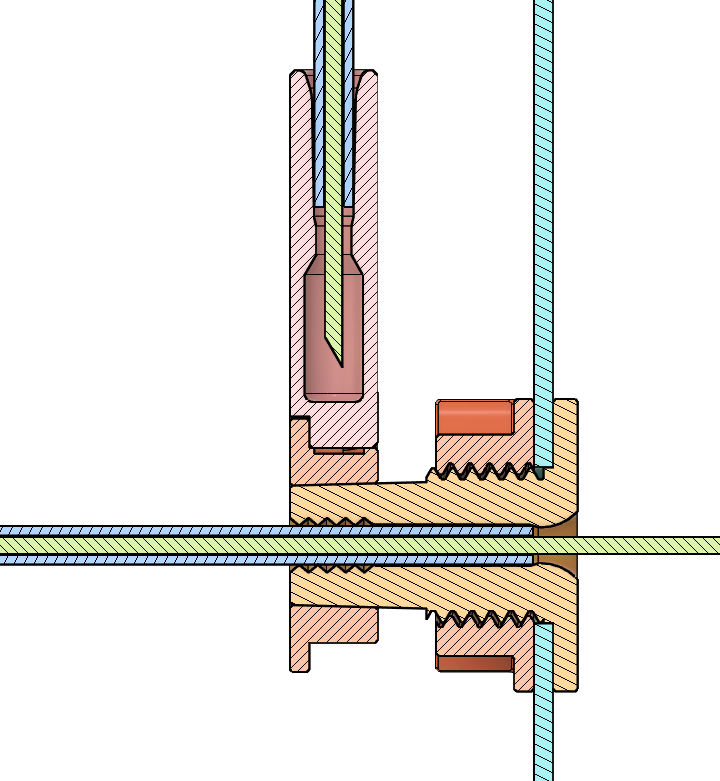

- 006500_Filament_Outlet_OD4_F## (PrintFit)

- 006600_Filament_Outlet_OD5_F## (PrintFit)

- 006700_Nut_T## (PrintFit)

- 006800_Clamping_Ring_W## (PrintFit)

- 006900_Plug_Variant_A_OD4_F## (PrintFit)

- 007000_Plug_Variant_A_OD5_F## (PrintFit)

- 007100_Plug_Variant_B_OD4_F## (PrintFit)

- 007200_Plug_Variant_B_OD5_F## (PrintFit)

- 007300_Silica_Gel_Clip_H3

- 007300_Silica_Gel_Clip_H12

- 007400_Silica_Gel_Screw_T## (PrintFit)

- 007500_Silica_Gel_Bag_Bracket

- 007600_Silica_Gel_Bag_Side_Support_F## (PrintFit)

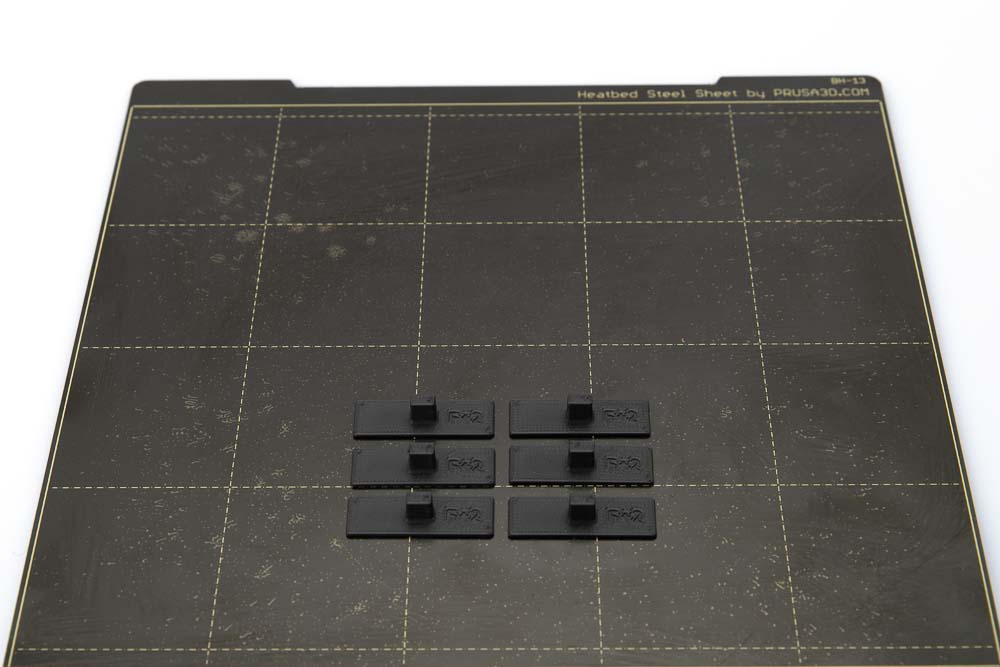

- 008200_Clip_Variant_A

- 008300_Clip_Variant_B

- 008400_Contrast_Plate_F## (PrintFit)

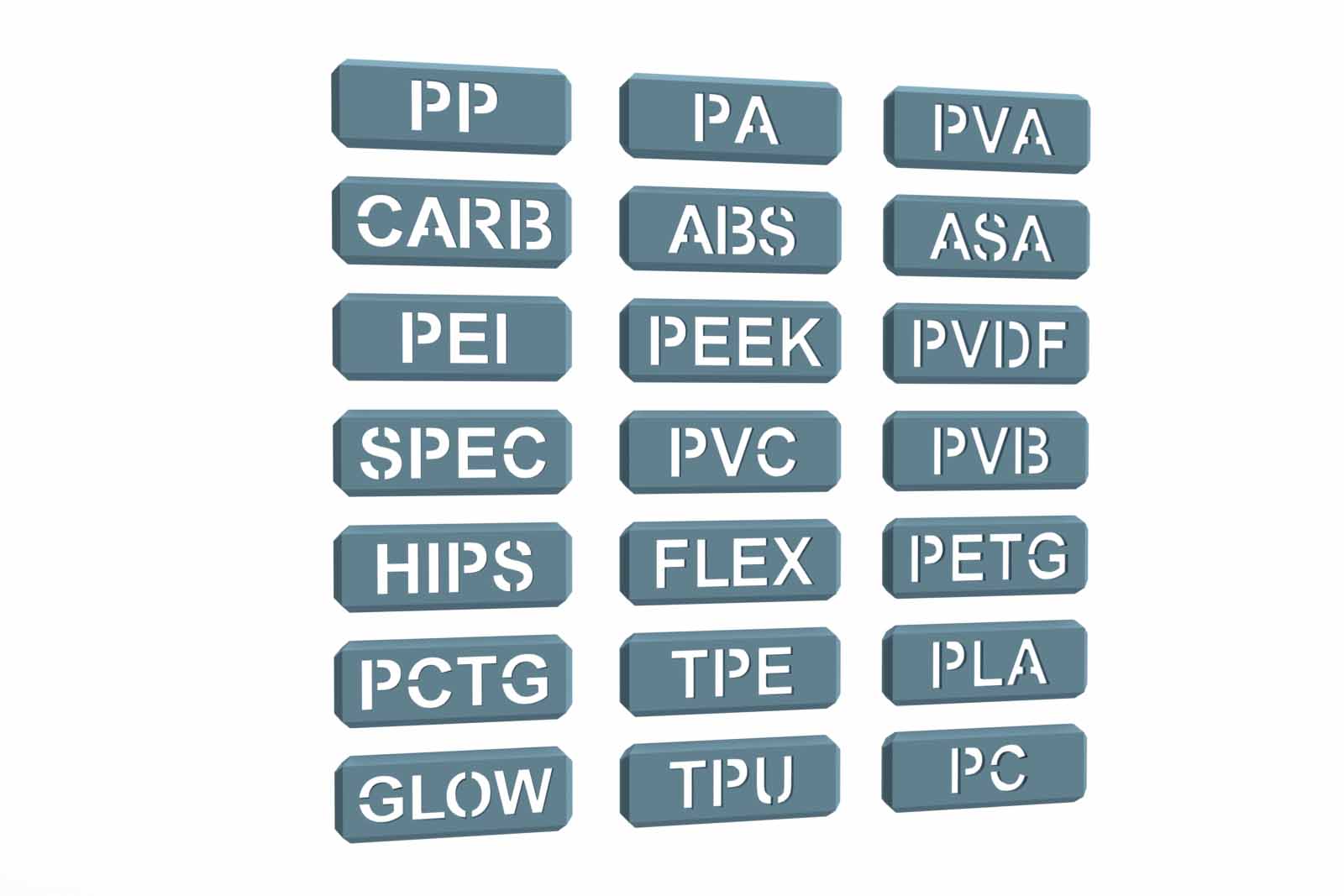

- 008500_ABS_Sign

- 008600_ASA_Sign

- 008700_CARB_Sign

- 008800_FLEX_Sign

- 008900_GLOW_Sign

- 009000_HIPS_Sign

- 009100_PA_Sign

- 009200_PC_Sign

- 009300_PCTG_Sign

- 009400_PEEK_Sign

- 009500_PEI_Sign

- 009600_PETG_Sign

- 009700_PLA_Sign

- 009800_PP_Sign

- 009900_PVA_Sign

- 010000_PVB_Sign

- 010100_PVC_Sign

- 010200_PVDF_Sign

- 010300_SPEC_Sign

- 010400_TPE_Sign

- 010500_TPU_Sign

- 010900_Samla_Fastener_22L_I## (PrintFit)

- 011000_Samla_Fastener_45L_I## (PrintFit)

- 000400_Tool_Bearing_Press_In

- 000500_Tool_Bearing_Press_Out

- 000600_Tool_Bearing_Press_Counter

Safety first! Read and follow the safety guidelines in the Operating manual of the DIY filament box.

Do you like the project? Support 3d-print-files.com and share pictures in your social media channels. Also send photos of your finished project to support@3d-druck-vorlagen.de for publication here in the product gallery.

The files are intended for private use only, commercial use (sale of the printed parts) and distribution of the files is not permitted, see the Terms and Conditions for more information. If you want to sell printed parts commercially, contact me by email for a license.

With the download link received, the files can be downloaded a maximum of 5 times.

If you have any questions about the product, please send me an email to support@3d-druck-vorlagen.de.

3 reviews for 3D Print Files – DIY Filament Box – ANYBOX Version 2023

Only logged in customers who have purchased this product may leave a review.

Stefan Camenzind –

I have to say, with the new 2023 update I am now completely satisfied with the box.

I Built 2 boxes and have been using them for a couple of months now. It takes some time to build them but it’s deffinitively worth it.

Verified purchase. Find out more

CEMAL OZCELIK –

I just bought this model and thank you for your effort on detailed instructions and beautiful design! I am a product designer and I was thought a design exacly like this project for my Printer Room. I wanted to check exist works to get inspired and I saw your model first. Then I quit in my project and I wanted to support your effort by purchasing this project.

I am founder of Craycle Hobby. We are building 3D Printed RC Aircrafts purposed for hobby. I hope you can continue to design new things!

Best Regards,

Cemal OZCELIK.

Verified purchase. Find out more

Taylor –

I’m just leaving off a star because putting this together is hell. Everything – from the screws and filament outlets to the ball bearings. It seems shrinkage wasn’t accounted for in the design. I’ve got to give credit to the author though for putting together such a detailed product with instructions and even including different variants for a customer to choose from. Very, very well thought out! I can’t think of anything else that’s comparable to it.

Purchase not verified. Find out more

Marian –

Hi Taylor,

thank you very much for your review and compliments! I am working hard on giving the best and most professional projects, 3D print files and instructions to you. I’m sorry to hear that the tolerances were too tight for you and you suffered through the assembly. To get this right for every printer is a quite difficult thing, because of all the different 3D printers, settings, filaments, tolerances of purchased parts and so on.

If you run in one of these part tolerance problems in 3D printing, the scale function of the silcer is a way to tackle these. Just print one test part (nut or pulley for the ball bearing in this case) and check if the assembly is ok, if it is too tight just scale up the X and Y dimension of the part a little bit (maybe 3 %) in the slicer and try again. Redo if it’s still not good, so you get to the optimal setting for you and your setup.

But for easier handling I’m already thinking of additionally add variation models of the nut and pulley with a larger thread and hole diameter in the next update of the filament box. If it’s ok for you I would like to send you the additional files for a test on your setup?

Happy printing and best regards

Marian

Marian –

This is the 2023 update of my Reply.

Hi Taylor!

I worked hard to find a way to eliminate tolerance problems (like the one you described) and found a solution: the PrintFit System

The new version (Version 2023) of the Filament Box STL files has five! models of each important part with slightly different dimensions, so you can easily adapt if a fit is too tight or too wide.

This helps to deliver the right parts, even if a printer is not super fine calibrated or especially tuned.

Happy printing and best regards!

Marian